As suggested in my Tabernacle discovery article, my unexpected encounter with π (the Pi constant) in Exodus texts would be just the beginning of my unusual Tabernacle journey.

Strongly suspecting that the discovery

of the mathematical anomaly had some significance with respect to the overall structure design, I felt it was incumbent upon me to further research the 314 appearance—not really knowing where it might take me.

Of course, I immediately understood that the path that I was walking would be an uncharted one—or an ancient one that was so obscured that there would be no markers along the way—or divinely planted hints that would

require a leap of faith to follow.

In continuing in my exploration of the Exodus account, I knew that it would be necessary to begin by surrendering any preconceived notions about the Tabernacle’s rectangular configuration—as collectively portrayed by religious

publications and establishments for perhaps thousands of years. After all, the 314 or π constant is associated with round shapes such as circles, cylinders, rings, and spheres, as opposed to rectangles, cubes, triangles,

or pyramids. So, armed with this single mathematical clue, I formulated a very simple hypothesis, suspecting that the Tabernacle structure—whatever it was—was bound to be round. Logically, this hypothesis would

need to be some way validated or confirmed before this strange 314 Exodus Tabernacle discovery really could go anywhere.

Needless to say, this hypothesis and research that I was about to begin would be—by its very definition—unorthodox; and I must confess that embarking upon the journey was as disconcerting as it was exciting. After all,

I strongly suspected that there would be nobody—dead or alive—that could show me the path, and even if I did succeed, those entrenched in the religious establishments were almost certain to doubt and even discourage

me along the way. After all, in the world of expert theologians, I’m officially an untrained and uncredentialed nobody. Moreover, apart from Moses’ account, there would be no historical archives upon which I could rely, and what

I was about to attempt was completely without precedent—at least in modern times among religious institutions and academic circles. Thus, even if I could prove everything from science and Scripture, tradition and institution

alike would logically be reluctant to accept proof or argument contrary to the status quo.

Apart from potential opposition from schools and scholars, the historical artifacts and literature that have survived from Jerusalem’s first and second temple periods are relatively few and far between (the existence

of the Temples themselves is even subject to ongoing debate), and relative to that more recent era, the amount of archaeological evidence dating back to the Exodus and Tabernacle times (around 1440 BC) is all the more

scarce and scientifically inconclusive. Thus, lacking authentic Tabernacle remains or other physical evidence, historians and archaeologists without hard data will ultimately find themselves at the mercy of religious

tradition, such as Josephus’ dimensional description of a rectangular Tabernacle, which obviously could not have been obtained by means of a personal observation. After all, given the ten century gap of time between

Josephus and the Tabernacle, it stands to reason that Josephus’ writings were gleaned from other fragmented second-hand accounts of unknown origins and questionable sources, particularly as they contradict Moses’ instructions

in several places. Nevertheless, because a source is from the ancient world and in agreement with present day traditions, scholars tend to presume that it must be true, and would be reluctant to treat Josephus’ regurgitated account

as if it is mere conjecture or hearsay.

Similarly, it would be unlikely for scholars to consider that Josephus' record is a byproduct of a thousand years of other influences, including urban architecture, catastrophic exile, bad scholarship or careless inference.

Of

course to the contrary, history is replete with round building precedents. Apart from the Bible, indigenous and nomadic people alike on every continent have a heritage of dwelling in round structures, be they igloos, grass huts,

or nomadic tents, dating back thousands of years. Curiously, the Hebrew word גר meaning “to sojourn” and pronounced “ger” is phonetically identical or at least similar to the word used to describe a round tent in multiple

languages spanning continents of Asia, Africa, and Europe (typically called a yurt, ger, or gert). Hence, simple etymological correlations and ancient construction practices also keep the round

Tabernacle hypothesis from sounding like a ridiculous or far-fetched idea—even though such reasonable arguments cannot be presented as anything but circumstantial evidence.

Seeing that precedent was in my favor, and knowing that no known historical Tabernacle record could discredit my hypothesis, my sense of optimism was even further emboldened as I surveyed collections of renderings and commentaries

as produced by artists and theologians, along with English Bible translations. First and foremost, I found that the designs and explanations to be not only inconsistent with one another, but also at odds with the Exodus

Bible texts and translations. Academically speaking, the lack of attention to detail and adherence to the Bible texts, in many cases, can only be described as embarrassing. Most artists pay no mind to units, quantities,

scales, proportions, weights, or natural processes; and the same can be said of commentators, who also violate simple laws of logic and language, demonstrate poor reading comprehension, and lack basic construction knowledge

and critical thinking skills. These contractions, however, are generally overlooked by an apathetic public that is usually inclined and encouraged to look at the “bigger picture” before giving consideration to detail.

Moreover, from an engineers’ point of view, the more the rectangular tent is examined, the more impractical, laughable, and even abysmal the assumed design seems to be. To the trained eye, it became clear that there is “nothing new under the sun”, and that each model, commentary, and translation is always built by borrowed traditions—where ideas are recycled and mistakes are systematically parroted. In fact, the more that I familiarized myself with the traditional rectangular Tabernacle narratives and the Exodus texts, the more they began to resemble the byproduct of what is commonly referred to as the “telephone game”, where multiple players arranged in a line or circle sequentially whisper messages in the ears of their neighbor until the original message content reaches the end in some bizarre and distorted version of the original. Fortunately, suspending any credence that I otherwise would have given the traditional Tabernacle model came quite naturally; and conversely, the lingering and occasional doubts that I had would fuel my expectation for reason in the Exodus text.

Finally, in pondering the merit of my new round Tabernacle hypothesis relative to the rectangular assumptions as embraced by the status quo, my personal experience in study of the Hebrew Bible also gave me an added measure

of confidence. After all, on a number of occasions, my rabbit-trail studies have regularly left me in stark opposition to popular religious doctrines, establishments, and perhaps most significantly, English Bible translations.

I was forced to conclude that if my experience in unearthing mistranslations in the past was any indication of the quality of translations I could expect in the context of the Tabernacle instructions, which were both

Hebrew and technical, I figured it was unlikely that my research tangent wouldn’t leave me disappointed or leave me stranded at a dead end.

As I began with a round Tabernacle hypothesis, discerning the design details of the ancient Tent of Meeting became relatively easy. The more roadblocks that I encountered in the English Bible text, the more solutions that

I found in the Hebrew Book of Exodus—as if the book itself wanted to shout out its secrets that have been hidden for so many centuries. It seemed that the more that I stared at the Hebrew text, the more the text stared

back at me. Parts of Exodus began to read like an engineering specification, with other parts reading like an as-built description, and with other portions sounding like a fabrication or construction plan. The first

clue gave way to another revelation, and the next revelation opened another door to discovery, and so forth, and so on.

As understanding of Bible texts is built precept-upon-precept, the revelation persisted in a rather progressive fashion. It was a little like setting up a modern tent without seeing any pictures with a bag of parts just dumped out on the ground. Nevertheless, when the item quantities and descriptions of the literal Hebrew texts were considered, everything matched in number and in function, and it seemed as if the ancient dwelling place literally wanted to build itself. The pieces of Exodus account which once seemed to be incongruent, esoteric, or nonsensical began to harmonize like notes played by different instruments in a symphony. As the various translation pitfalls and problems were identified, numerous etymology and interpretation problems that have been perplexing scholars for countless generations were easily overcome.

Like puzzle pieces coming together or data points connecting together to form a curve, the addition of each new point or piece made the end result that much more evident. Every Tabernacle part and feature described in Exodus has a clear and obvious purpose when presuming a round structure configuration; likewise, simple volume and sizing calculations demonstrated that all hardware pieces could be constructed in accordance with the material quantities as specified, which traditionalists will scarcely consider in their exegesis and commentary. When the Hebrew is revered as infallible and authoritative, it becomes clear why every jot and tittle of the revelation was important, and why Moses’ law emphatically forbids making changes to the content (Deuteronomy 4:2). In other words, in assuming a round Tabernacle model, the language worked, the math worked, parts were provided in reasonable sizes and quantities, and the engineering checked out. Having discovered the mobile six story architectural and engineering marvel that which was lost to billions of people for over 2500 years, needless to say, I was elated. Nevertheless, and much to my surprise, the technical and linguistic analysis aspects of the project would prove to be the easy part.

Having deciphered the Exodus tent size and shape in a relatively short period of time with nothing but the Hebrew Exodus texts and a Hebrew concordance, I figured that introducing this discovery to the religious community would be “easy as pie”, or, if as the mathematicians might say, “easy as π”. After all, the two decimal point approximation of π that the Hebrews had recorded was more accurate than known to any other culture of that period, and could be easily demonstrated from just a handful of verses from the plain Exodus text—even from many English translations. In publicly disclosing my findings, I figured that the discovery would rapidly propagate throughout the internet via social media firestorm. Explaining the π discovery and presenting the sum of much of my other research graphically, I launched a dedicated website to publish my findings (http://project314.org/, now revised), which was launched March of 2015, on 3/14/15, which, numerically speaking, is none other than the “Pi day” of the century. Adding to the intrigue, the scheduled Scripture reading according to the ancient Jewish liturgical calendar for 3/14/15 was Pekudei (פְקוּדֵי), which is the second Exodus account of the Tabernacle construction (Exodus 38:21-40:38). But the results of launching the website and project were not quite what I had expected.

Although there was some interest generated by the initial 3/14/15 website debut, it seemed that the social media posting and bulk email distribution to my personal contacts had limited reach and seemed to generate little public interest. As the amount of organically propagated follow-up traffic seemed to be fractional after 3/14/15, I began to speculate that the interest it generated was almost solely based upon π and its enigmatic history, and peoples’ interest in celebrating the pseudo-holiday as defined by numeric coincidence (Gregorian calendar dates are generally thought to be of little prophetic significance according to strict religious purists and Bible prophecy junkies). It was as if people thought my discovery and research to be contrived based upon a parlor trick or gimmick, and as a result not worth exploring or testing. The fact that this 314 constant was related to the only divinely specified structure of record in all of human history seemed to be of little interest.

Given the project novelty and the seemingly extraordinary and outlandish claims that I was making (implicitly proposing in effect that I am right and everyone else is wrong), I was not completely shocked, overly disappointed, or highly discouraged by the soft initial public response that followed the website launch. After all, is easy for people to become dogmatic or indoctrinated, and a combination of faith in religious establishments and cognitive dissonance keeps people from thinking outside of the box. Nevertheless, and despite the fact that the external responses and inquiries that I received pertaining to the Tabernacle rediscovery were few and far between, I remained steadfast in the project vision and merit of the Tabernacle discovery, as I had the raw data, Biblical texts, and firsthand experiential witness to back up my convictions.

Back in 2015, as the project was still in its infancy, I believed that it was just a matter of time before the Round Tabernacle propaganda and research materials fell in the lap of someone who was insightful, intelligent, and influential enough to come to terms with the Project 314 research and recognize the depth and amazing breadth of the round Tabernacle discovery.

Understanding the importance of having a highly concise and bilingual (Hebraic / English) resource that would help facilitate project endorsement, I first officially published a set drawings on 3/14/15, which I’ve come to refer to as “EEE” or “Exodus Engineering Exegesis” drawings on a traditional engineering title block. As I distilled the entire Tabernacle exegesis down to a mere four pages of illustrations, I figured it would be easy for users to follow along, as tables and hardware items were presented in a concise verse-by-verse fashion, and translation clarifications were included as need be on a word-by-word basis.

Being no more complicated than a set of consumer-grade assembly instructions one might receive in an IKEA modular furniture kit, I figured it would just be a matter of time before someone of academic stature or public notoriety would recognize and testify on behalf of the discovery that I made and the validity of my research and conclusions. But over the course of many months, after drafting many letters, printing many drawings, and making many trips to the post office, it would seem that my quest to find subject matter experts to participate in the game of research review and advocacy would ultimately prove to be naïve as well.

As a result of my efforts in seeking something resembling a so-called “peer review” of my Hebrew Tabernacle exegesis, I came to perceive that almost all “subject matter experts” have several things in common. First and

foremost, and to their credit, it is clear that said experts are seldom devoid of their own ambitions and priorities. In other words, they typically have families, jobs, and mortgages; and as such, reviewing or validating

someone else’s research seldom makes their list of monthly or even annual priorities. From this standpoint, and from typical responses, I figure that reviewing my research ranked somewhere between changing the lawnmower

oil and cleaning out the dust beneath and behind the refrigerator. But perhaps I greater problem that I encountered is that most religious subject matter experts lack technical training to validate or refute the results of my research. Hence, most

subject matter experts are very reluctant, rightfully so, to speak outside of their predefined areas of expertise (realizing that many specialized “experts” are, by definition, people who understand almost everything about almost

nothing). In other words, the formula of "Availability + Technical Background + Hebrew Literacy + Credential + Notoriety + Tabernacle Familiarity", or (A+TB+HL+C+N+TF), statistically speaking, began to look like an asymptotic line approaching zero.

However, there is a darker side to the lack of cooperation that I experienced. For obvious reasons, there is bound to be some measure of stigma for those who have taught the traditional rectangular Tabernacle model over the course of their careers. Thus, in some cases, some might fear that embracing a new paradigm would ultimately undermine their own authority or credibility. Likewise, with some of the academic pools being inherently specialized, shallow, and small, some may legitimately fear that offering endorsement would result in conflicts of interest, which might logically result in institutional backlash, with their own job security being threatened as a result of speaking contrary to the status quo. While in some cases there may not be an appreciable threat to their vocation, endorsement of an unconventional doctrine can also alienate people within certain professional and social circles. As I am personally not a member of any institution or academic “good old boys club”—that furthers itself primarily by means of mutual back scratching and favor trading—there is seldom any sense of incentive for subject matter experts to invest in an endorsement of a theory or discovery that is not their own or from within their own familiar ranks or institutions. Especially when a paradigm shift as radical as the round Tabernacle is introduced. In endorsing unorthodox material, there’s also the matter of endorsing an unfamiliar face with an unconventional background. In other words, who wants to vouch for a “nobody” or an “outsider”—especially one who is unknown and therefore unpredictable—given the risk with no reward apart from truth and understanding?

Although my present inclination to seek more professional endorsement continues to diminish on a daily basis, I do continue to entertain recommendations from religious “pedestrians” (i.e., people who are not professional clergy or theologians but are amazed by the Round Tabernacle discovery) from time to time, who are often inclined to refer me to their favorite religious authority, celebrity teacher, religious guru, etc. Unfortunately, experience has consistently shown that these efforts are generally a poor return on investment, or at best case, are a long shot, and as a result I will seldom try to engage such figures unless formally and even personally introduced. While some people have been disappointed as I politely turned down their advice to contact their favored religious personality, it seems that few will consider agreeing to the reciprocal, whereby I propose that they are the ones making a concerted effort to try to serve as an advocate or agent on my behalf in presenting the Project 314 research and findings to their guru of favored status.

While I’ve tried to keep an open mind and engage experts for the sake of humility, integrity, courtesy, posterity, accountability, education, growth, and optimism, I must confess that I have come to grow weary of seeking out experts and

asking for their “blessing” or their permission. After all, I’m not exactly trying to kiss the back of the hand of some shadowy Godfather-esque figure so that I might get permission to operate in his jurisdiction, or

trying to navigate some elaborate esoteric social labyrinth or climb some hierarchy in order to be declared legitimate. To the contrary, this Tabernacle research and restoration effort isn’t all about about or from me; however, I am convinced that the research stands upon the authority of the word

from which it is derived. Furthermore, experience has often shown that experts are often respond as if they are being set up or ambushed, often responding with evasive language or sometimes a blank

stare—like deer blinded by the headlights of an oncoming car.

Whenever I am confronted by a man who leads and defines himself by means of academic certifications or accolades, I often reflect back on the humorous remarks of my hydraulics professor, who said that an “expert” was a “has-been” (ex)

“drip under pressure” (spurt).

As I generally do not regret making various efforts to reach out to respected characters in academic circles and religious communities, I can also say that from a fairly early point in the project, I quickly came to see the limitations, patterns, and pitfalls of seeking endorsement, and inherently knew that “you can’t become tall by standing upon the shoulders of giants”. Furthermore, I knew that I shouldn’t be so eager to seek endorsement—or so-called “peer review”—from the institutions and communities that seem to automatically issue academic credentials to people devoid of critical thinking or comprehension skills, as described above. Thus, given all of the barriers, I had the feeling that for the Tabernacle project to stand a chance, it must transcend institutional credentials, and it must be a movement “for the people” and to a large degree, “by the people”. The campaign would need have to enough grassroots appeal, whereby the watering and lighting of the good seed below that is otherwise trodden underfoot and robbed from taller weeds choking out the roots below and stealing all of the sun from above.

In the fall of 2015, I was able to acquire feedback on the Tabernacle exegesis on a more personable and a much larger scale, as I presented four unique PowerPoint presentations at a Feast of Tabernacles gathering in a central United States location. Using physical props and assistance from the live audience, I was able to quickly demonstrate the π-based math that was revealed in the Exodus text. During the first presentation, the audience seemed spellbound, or at the very least, caught completely off guard. I cannot recall the exact line of questions subsequent to the first brief and partial presentation, but it seemed that the vast majority of the audience found the idea to be plausible—and perhaps even probable.

Despite the warm overall response, I was confronted with two memorable objections as I concluded my first public presentation. One of the two objections was of a technical nature (presuming a rectangular shape based upon the two “corner” beams per Exodus 26:23-24) and presented to me by a man who seemed teeming with pride (thinking he found a a hole in my research in the well-worn pages of his KJV Bible) yet approaching the problem with a divinely-inspired-English-translation mentality. However, of greater significance, I recall one audience member being frank enough to challenge my credibility, albeit politely, in public. Seeming to be motivated by skepticism, he wondered why I (i.e., a novice and non-native Hebrew student) was able to decipher and translate texts that the Jews (as keepers of the Hebrew language and fluent speakers of the language today) and professional Christian theologians (including translators who are dedicated to the study of the ancient language) were unable to decipher properly for the last two thousand years.

Based on the line of questioning, I learned several important lessons and was shown several unfortunate realities that day. First, it was clear from the audience reaction that almost nobody present had any real command over the Tabernacle subject matter, whether it is rooted in tradition or translation or not. Second, it seems that religious people trust credential, translation, and tradition over reason. Thirdly, I was probably a “nobody” in the eyes of at least some of the audience members, and nobody expects anything from a “nobody”. To the contrary, people would rather be led by fame or credential than truth or ration, and most people will not follow truth without the expressed consent of their favorite religious figurehead.

While I have no intention to resort to violence or gangster tactics in order to influence audience members, it’s probably fitting for me to open up my presentations with the tagline, “I’m going to make you an exegesis you

cannot refuse”. I say this because given a couple of hours to discuss the details of the Tabernacle texts with visual aids, I find that there is seldom a single person in the audience who is remotely capable of objecting

to the exegesis of the Exodus text that I present—and at the conclusion of my presentation, most are willing to claim to be converted. However, in most cases, I’ve come to suspect that the lack of objection to my presentation

material is more than likely rooted in the audience’s overall ignorance of the subject matter as opposed to what I believe to be my own superior command of it. I say this not to be deliberately demeaning, condescending,

or boastful, but to be practical, objective, and realistic, especially as I personally had virtually no command of the subject matter myself as little as five years ago. Nevertheless, based upon the depth and the details

of my research, I feel that I can substantiate the Round Tabernacle claim without compromise—even if I went up in debate against the world’s foremost Hebrew Bible experts. To date, I have yet to be challenged in formal

debate, as every technical engagement I have experienced to date seems to go uncontested or met with evasive tactics and language.

Convinced that a video-based social media campaign would be essential to project success, I began to search for viable video production services and tools back in late 2015, as I was intending to lead with a professional

grade video trailer. Being unable to find—or afford—the talent that I wanted or needed to help with video development, I began to work on developing my own video production capability, learning some script writing,

software animation, and video editing basics. As expertise in the art of videography cannot be attained overnight, my efforts in this endeavor came to an unexpected—yet welcome—interruption. The interruption came about

as a result of my internet radio debut on Rob Skiba’s Truth Frequency Radio show, which was aired in early 2016.

Not long after the interview aired, an experienced professional tool and die maker reached out to me, expressing his interest in making a small scale model of the Tabernacle. Determining that a 1/40th scale tabletop model would be appropriate for shows, home enthusiasts, as well as schools or museums, I developed a complete set of manufacturing drawings—complete with manufacturing dimensions and tolerances—to meet the fabrication needs of both a macro (full scale) and a micro model. After investing many hours in dimensioning and detailing each piece of hardware required to make a the tent model, I also developed a detailed set of illustrated erection plans, which ultimately required that I qualify the interim conditions of the structure during the erection process by means of additional engineering calculations. After all, if the large six-story yurt-like tent frame that I am deducing from Bible texts—featuring a ring weighing perhaps 13 tons—cannot be realistically erected in the wilderness, it is pointless to claim that the model that I claim to have discovered is a viable one. Unfortunately, after investing months of effort into detailed diagrams, calculations, and procedures, it came to pass that the model maker’s availability became extremely limited. As such, the short term benefit of my detailed engineering and drafting work could not be realized at that time, and as a result, I endeavored to return to development of video content while the suitcase-sized scale model plans would be shelved for another day.

Perceiving that an intriguing storyline and compelling testimonies would fill a number of project promotional needs, I made arrangements to return to Israel in the late summer of 2016, with the intention of recording travelogue

and interview video content suitable for the making of a documentary of sorts. Although my cameraman friend and helper fell under the weather unexpectedly for a good portion of the trip, I was nevertheless able to tour and shoot some video of a

number of important sites and interesting personalities during my trip.

While I was able to seek audience with a few prominent and amazing people while in Israel, I was really most interested in seeing the “man

on the street” reaction to my research—especially given my previous experiences in seeking viable “Tabernacle subject matter experts” in the United States. Having lived in Jerusalem for a period of time several years prior, I knew my way around fairly

well, but this is not to say that I had any idea as to how the native Hebrew-speaking Jews—be they secular or religious—would react to my discovery and research.

From my past experiences living among the Jewish community in Israel, I first suspected that most religious Jews would be more steeped in tradition and therefore difficult to convince than their American Christian counterparts.

However, after being in country for just a few days, I was delighted to find that I was largely mistaken in my assumption. In fact, I found the majority of religious and pseudo-secular Jews to be curious, engaging,

and academically honest—not to mention extremely well educated. Contrary to the majority of American Christians I encountered, it was clear over the course of conversation that a majority of Jews had an exceptional

command of the Exodus Tabernacle texts (not only by American standards, but it seemed like a good number of religious Jews had the text committed to memory in varying degrees).

While I was loaded down with backpacks full of recording gear and project promotional props (including Bibles, binders, books, curtain miniatures, etc.) to better

convey my point, I found that in most cases I was able to defer to my four-page Hebrew exegesis drawings for most of my explanations. Given that my audience was usually intimately familiar with the subject matter and

the language, it made the presentation of my Tabernacle research feel as if it was almost instantaneous—like a 100mbps broadband. In fact, I could usually walk religious Jews through my laminated sheet set in about three to five minutes, at which point, they seemed to understand and absorb what I was proposing.

I must confess that it was extremely ironic, comical, and even a little embarrassing at times as I endeavored to explain the meaning of the Hebrew Bible texts to fluent and religious Jews, especially as I stumbled

through the my own familiar materials using my adolescent Hebrew, which they were bound to receive as crude and remedial. Nevertheless, for those willing to discuss the matter, it seems that the vast majority of Jews were very

open to the idea, with the more religiously committed ones open to accepting it as a “possibility”—at least on a pluralistic basis. I would venture to guess that Jewish acceptance of the possibility of a round Tabernacle

(while coincidentally accepting the traditional rectangular paradigm) is rooted in Jewish upbringing in environments where Torah and Talmudic midrash is commonplace, whereby they are openly encouraged to question things

and are likewise expected to substantiate their widely varying personal opinions. Per my perceptions and experience, it seems that Jews are much more open to “both-and” systems of thought and scenarios given their traditions, and contrary to my expectations, far less likely to insist upon “either-or”

paradigms than their western Anglicized Christian counterparts.

Although often times I was not fluent or quick enough to decipher their spoken Hebrew response to seeing the research, fortunately, the "aaaaahhhh" or “ah-ha” verbal response needs no translation. As circumstance generally did not allow for candid video capture of these moments, there were also usually a number of “I get it” facial expressions that accompanied the sounds. However, was also a number of other facial expressions that followed the initial "I get it" response that words can scarcely describe. Sometimes, it was an expression of joy and amazement, other times their faces conveyed insecurity or uncertainty, and still other times a confused mixture of anger or hostility or suppressed, perhaps as a result of the far-reaching implications of the Tabernacle paradigm shift. Pending further discussion, I came to perceive that some of the obstacles common to American Christian counterparts were also common to the Jews.

As is the case with American Christians, a notable portion of the Israeli Jews surveyed, it seemed, were not quite emotionally equipped to process what they had been shown. For those that seemed unwilling to commit to

the round Tabernacle, they generally refrained from doing so as a result of a lopsided commitment to what they perceived to be “unity”, which was defined by a strong faith in the wisdom and integrity of their sages,

and their commitment to their tradition irrespective of evidence to the contrary. The reactions of some people that I engaged might be compared to those under the spell of some form of trauma-based mind control, whereby they looked

nervous when pressed for a decision or opinion, seeming to need official permission to believe something other than what their particular brand of religious authority had handed them. Regardless of how intelligent they were—and most of

them appeared to be very knowledgeable and rational—it’s as if someone had bullied or intimidated them in the past, brow beating them into submission. Consequentially, after I presented my research to them, they often seemed morally

conflicted. More specifically, many seemed unable to make peace between the many good truths contained within their faith and tradition while concurrently accounting for this new “fly in the ointment”, which came straight

from the written Torah without the need for conditional clauses, exhausting commentaries, and traditions galore. Being approached without warning or time to sit and study out the matter in their leisure, it seems that the round Tabernacle

paradigm left them subconsciously perplexed, as the juxtaposition would leave them questioning as to what is sacred and what us profane in a way that nothing else that they had been previously seen had done before.

Of the extreme minority that opposed the Round Tabernacle paradigm and exegesis outright, they seemed to oppose it very automatically and with hostility, without demonstrating much patience, objectivity, academic integrity, or articulated reason from the Hebrew Scriptures. Some of this more extreme minority played the privileged race and religious zealot card—suggesting immediately that because I was Jewish I couldn’t possibly know what I was talking about (although my EFL/HSL status may explain this premeditated bias). Ironically, these same people were unable to explain as to why two Jewish sages, such as Rashi and Ramban, were allowed to completely disagree on many details as to how the Tabernacle was built—yet were allowed to be considered as equally valid sources for no other reason than them being Jewish. Those failing to offer any arguments or rebuttals of substance against my explanation—or in favor of their own—seemed to believe that if you were Jewish and wrong you were still right and able to endorse mutually exclusive “truths”, and if you were right and not Jewish, you were wrong (and quite possibly even antisemitic) if you opposed multiple contradicting Jewish traditions simply because you weren’t Jewish. I am grateful that this description fits an extreme minority of the people I encountered and queried in Israel.

As discussions concluded, it was not uncommon for anyone—be they enthusiasts, fence riders, or antagonists—to suggest that I go and discuss my research with their favorite or neighborhood subject matter expert. Because I traveled to Israel for this very purpose, I was eager to discuss my findings with Jewish experts, and made a point to follow up with their recommendations in Israel where and when I could. However, in most cases, I fear that the recommendation to talk to their rabbi was not primarily rooted in generosity or exuberant confidence in what I was sharing, but was rather motivated by their lack of self-confidence and skepticism—or possibly disinterest in the topic from the start. From these responses, it seems that what many people really wanted was someone else’s permission or instructions to believe something different, as I suspect that they had become accustomed to absolving themselves of personal responsibility by means of deferring to their local authority. As there always seemed to be additional strings attached and obstacles to talking with their “religious superman” figure, it became frustrating time and time again as I came to the many dead ends while traveling along the path of “Subject-Matter-Expert Boulevard”.

In any case, apart from open-minded yet pluralistic tendencies, I found that Israeli Jews had a very difficult time contextualizing the significance of the Project 314 Tabernacle discovery and research. By this, I mean that most Jews

couldn’t seem to see any value to returning to a Tabernacle; as for two thousand plus years, they had their minds completely fixed on the Temple. Even though pro-Torah Judaism typically studies the Exodus Tabernacle writings twice a

year in accordance with their liturgical calendar (during Terumah, Vayakhel, and Pekudei Parshot), it seems that their true religious dreams and aspirations are generally far more Jerusalem and Temple-centric. This is evident

by their book stores, which, from my experience, seldom even contain any Tabernacle study materials. Likewise, from looking at commercial goods and Judaica, one could easily surmise that the Jews as a whole long more for the

glorious days of David, Solomon, and the Temple, where the land of Judah became the center of Israel and the rest of the world, than they miss the days of the Exodus wilderness—when God’s revelation and presence came down from Mount Sinai in the midst of Israel's twelve nomadic tribes.

Whether in the United States or in Israel, I find that the vast majority of the people that I engage, even those who disagree with me, are typically polite in dialogue—but not always. Sometimes some of the more learned

and traveled people that I’ve introduced my research to will say, “What about Shiloh?” To this, my answer is, “what about it?” After I say this, they engage me in a sort of condescending way, and as if I’m completely

ignorant, they go on to lecture me about how teams are sifting through archaeological remains at Shiloh, which is believed to be where the Tabernacle resided for nearly four centuries. While I did have the privilege of visiting Shiloh years before I embarking upon Tabernacle research, I was not made aware of definitive “evidence” that unconditionally proved that the Tabernacle was rectangular. Nevertheless, given Shiloh's importance and Tabernacle history, I knew it was essential to visit Shiloh on my 2016 Israel trip.

With the Old City of Jerusalem being commercialized for the sake of religious tourists, I’ll never forget the words of my Australian friend Jeff, who had worked as a missionary for a number of years of his life. As we were touring religious theater and remains in the Old City, Jeff tactfully said to me, “bells, smells, incense, and nonsense”. While Jeff and I both do believe that the city is in many ways Holy, this is not to say that cynics are not at least partially correct when they liken Jerusalem to “Disneyland for religious people”. It's one part faith, one part fact, and one part fairy tale. With plaques, rides, smoke, lights, sound effects, and actors, some places can be compared to a religious theme park.

Although ancient Shiloh is every bit as much of an Israeli government regulated dig site as it is a tourist attraction, it has been endowed with some special accommodations for the sake of tourist education—and entertainment. To help pique the tourists’ interests and imaginations, the Israelis have added a watchtower for tourists on a hilltop in the midst of the Shiloh park site over the course of recent years, which offers visitors a commanding view of the Shiloh site. On the inside of the stout tower, visitors are offered a break from the scorching summer sun, where they enjoy air-conditioned theater-style seating, a state-of-the-art surround sound system, and a high-tech panoramic video screen to play animations and prerecorded professional reenactments, which depicts bits and pieces about an ancient—and rectangular—wilderness Tabernacle. This virtual reality model presented inside, of course, tends to reinforce the rectangular narrative, which is literally cast in concrete in modern Shiloh. Just a few football fields away, residents erected a large synagogue designed to resemble the rectangular Tabernacle. Furthermore, tourists are able to see a rectangular plateau perimeter that is marked with a tribal flags to help feed the visitors' imagination. It is ironic, of course, that the new Shiloh tourist and watchtower is architecture of a unique—and round—design! Nevertheless, the Tabernacle images that are consistently depicted inside on the theater screens are consistently rectangular; consequentially, the same images and shapes are consequentially envisioned on the outside of the tower as well.

With imaginations seeded by legends—as opposed to Bible texts—not to mention the artwork, model kits, books, and figurines in the gift shop, it is easy for people to superimpose these images in their minds as they personally survey the ancient landscape. Although there is a platform created by a slab of rock at the northern edge of the Shiloh plateau (which would incidentally result in Tabernacle access restrictions and an egress nightmare) that seems to be the “tourists’ favorite” location for the ancient tent, this is not to say it is favored by archaeologists, who have in numerous articles written over the course of decades, which ultimately admit to the absence of definitive corroborating evidence.

Nevertheless, in recent years, people have found a couple of holes which they propose to be large post holes in the rocky ground, which are assumed to be used for the courtyard posts. Tabernacle courtyard post size and quantity, however, would not seem to allow for this explanation, as the rectangular courtyard is thought to employ a total of about 60 posts, with copper posts needing to be much smaller in diameter (based on the amount of copper allocated in Exodus) compared to the relatively massive cross section of the relatively shallow hole found in the bedrock.

But the show must go on— and as long as people continue to think that the Tabernacle was built like a shoebox, the longer people will stand in an empty field of rock thinking

that they are having a “spiritual experience” as their overactive imaginations has them are standing in the Holy of Holies before the Ark of the Covenant itself. To true religious enthusiasts, a Shiloh visit will teach

them nothing about the size or shape of the holy Tabernacle structure itself, but rather will likely only indulge them in more religious fantasy, which can be further reinforced by touring Israel’s two life-size rectangular

Tabernacle models, which can be found in Ariel (Jewish model) or Timna Park (Christian model).

At the onset of my 2016 Israel tour, a mutual friend introduced me to Adam Eliyahu Berkowitz, who is a features writer for Breaking Israel News. Being interested in the Torah and in the fulfillment of Bible prophecy and

identifying as an orthodox Jew, Adam seemed to be interested in meeting me from the very beginning—despite the highly unorthodox Tabernacle discovery claims I was boasting.

After almost two weeks of playing phone tag, Adam and I finally met face-to-face in a coffee house in Tiberas, which is the largest city that is situated along the Sea of Galilee. Over the course of the next few

hours, I relentlessly inundated poor Adam with my materials, showing him binders, scrolls, and drawings, which contained a condensed sum of my Tabernacle exegesis and research. Having studied Jewish law, Adam did a

pretty good job keeping up—seeing I was trying to force him to drink from a fire hose.

Not long after the interview, Breaking Israel News published Adam’s article about my ongoing Tabernacle research.

For the sake of brevity, Adam’s article mainly focused upon the various biblical and technical aspects of the Tabernacle discovery.

Granted, it is ironic that Breaking Israel News is published in English, and

it’s also ironic that I went all the way to Israel only to cultivate Hebrew and Jewish media leads; nevertheless, I consider my Breaking Israel News coverage to be quite a blessing and accomplishment, and an important

step in diversifying the project audience and social media reach. However, I must confess that when I first set out, I wanted to cultivate a much larger and stronger Jewish audience in Israel.

... for with stammering lips

and another tongue will

he speak to this people.

~ Isaiah 28:11 ~

...for out of Zion

shall go forth the law,

and the word of the LORD

from Jerusalem.

~ Isaiah 2:3 ~

Irrespective of personal preference, I do believe that I did both what I could and should do over the course of my brief 2016 summer tour. Moreover, I’ve also come to further appreciate the first publication being written in English, as English usage is extensive throughout the world and is prominent throughout the world-wide-web, not to mention easily adopted into other tongues. In fact, I was able to find the article to be mirrored or heavily cited in other languages, including Spanish, French, Chinese, Korean, Polish, Portuguese, Dutch, and Hebrew. Also, it seems that project-generated Tabernacle images that were incorporated into Adam’s article have come to regularly appear on the first page of a Google image search. Likewise, Adam’s rabbinical ordination and Orthodox Jewish perspective not only gave the project research a measure of credence, but Adam’s ongoing focus on prophecy and awakening of Israel in Diaspora are also particularly important aspects of his platform as well.

Of course, the Breaking Israel News article did not and could not address each and every aspect of my research or my Israel trip. But Adam’s article didn’t need to do so, and neither do I need to do so at this time.

After all, my encounters with university professors, rabbis, religious Jews, engineers, professional Temple restoration advocates, archaeologists, exhibitors, guides, and antiquities authorities may be interesting in their

own right, but they are not essential to engaging the Torah and the Scriptures at a very practical level. And this is something that Adam intuitively understood—thinking outside the box and thinking for himself—while everyone else was looking

for permission, looking to be absolved of risk and responsibility, and looking to make the law into something more complicated than it actually is. There’s a difference between knowing the path and walking the path,

and the simple truth is that telling you about my physical site research findings (e.g., Gilgal, Timna Park, Ariel, Shiloh, Gilgal Rephaim, the City of David, etc.) might help you better know the path, but it will not

inherently endow anyone with the confidence or the conviction to walk a new path.

Not long after returning from my Israel trip, three different engineers (two civil and the other mechanical) contacted me after hearing about my research from Rob Skiba, who did a follow-up video covering Adam’s Breaking

Israel News article. Brian, the first of the two to contact me, was curious as to the scope and content of the “Exodus Engineering Exegesis” drawings that I was advertising on my website. As I made efforts to respond

to Brian’s request for clarification, it became evident that Brian had interest in building a physical model. As Brian and I talked, it was clear that we had a good rapport, and shortly thereafter, I explained to Brian

that I had developed a completely different set of prints that I had created six months prior that was intended for the explicit purpose physical model fabrication, as well as for the erection procedure.

After receiving my extended stack of fabrication and erection plan drawings, Brian was impressed, and offered to help fund a “Home Depot” version of the Tabernacle model. When I say a “Home Depot” version of the model,

I mean a model that could be constructed from materials that were readily available at local lumberyard and/or hardware store. As it turns out, some of the materials, such as 2x4’s, could be locally sourced; however,

some of the materials (e.g., dowels and metal rods) needed to be ordered specially because they were not quite popular consumer grade materials. As we began to discuss optimization of materials, credible fabrication processes,

and substitution requirements, we eventually settled on a fractional scale model prototype design that was about 7 feet high and 22 feet in diameter. This size enabled us to base an economical model upon modified

2x4’s; however, the economy of the initial materials became a trivial factor in the overall effort relative to the labor and special tooling required to fabricate the parts according to specification.

As for modeling objectives, one of the principle goals in building a physical model would be to establish “proof of concept” for the Tabernacle model that I had deciphered from the Exodus texts. Could the Tabernacle structure

really be built exactly as the Hebrew Exodus Tabernacle texts had described the structure to be? When I say, “exactly as... Tabernacle texts had described”, I mean in exact proportion to the full size model. After

all, if the length and weight proportions between the smaller scale model and the large model did not match, however impressive it would be to fabricate, the purpose behind building a “proof of concept model” would be negated.

As I already knew relatively well what the full size model would require with respect to fabrication processes and tolerances from the fabrication plans that I had developed six months prior, I knew that I had to

get the services of—or access to—specialized talent or tools. Although I did get some budget quotes for fabricating some of the specialized pieces, I also came to conclude that it would ultimately be the most economical

for me to fabricate the parts with special shapes and features myself—provided that I could get access to the special tooling. Because operation of a precision computer controlled woodworking is not a common skill set, and because prototyping can be

a very iterative process, I decided to join the Milwaukee Maker Space, which is tool co-op group that shares a large rented shop space, whereby I could get access to computer controlled machines and a fully equipped

wood and metal shop.

In addition to a computer controlled Tormach metal milling machine, and a programmable wood router featuring 3-axis control and a large 4’x8’ bed, membership granted me 24 hour access to bandsaws, chop saws, table saws, jigsaws, drill presses, taps, dies, welders, buffers, grinders, sanders, lathes, jointers, planers, laser cutters, weaving looms, and leather working station. Not only was the tool and equipment arsenal impressive, but the access to knowledge and talent was impressive as well. As “the space” consisted of approximately 200 members and volunteers, including carpenters, machinists, welders, computer gurus, electricians, engineers, artists, and too many other eclectic specialists to mention, help was never too far away—and no job was impossible for the crew at the Milwaukee Maker Space. But this is not to say that all of the tasks that I performed under the Maker Space roof are expedient and efficient.

Knowing that this Tabernacle model was a prototype, I knew one thing—that I didn’t know quite what I should expect or how long it would take. Although I have worked as a professional engineer in a variety of industries, most of my practical “hands-on” wood and metal shop experience dates back to high school, and the three numerically controlled machines that I needed to use required special training. Sometimes there were equipment access conflicts, sometimes equipment was broken down or left in disrepair, and materials needed to be stowed away at the end of every workday. Also, I had to both redesign and remake a number of prototype parts from scratch, as it was clear that I didn’t have a few of the minor fabrication details thought through very well from the beginning. Given these factors, what I had hoped to accomplish in four weeks took more like four months. Of course, “hope” is never a good basis for a practical estimate, but my professional experience never left me with the knowledge base to estimate such a project with so many unknowns with any level of precision or accuracy. When I set out, I wasn’t so naïve as to think that I would be able to finish the modeling project with no setbacks or in accordance with personal timeline preference, but it is nevertheless discouraging when things take longer than expected.

Once the fabrication of the individual frame parts was completed in March of 2017, I was ready to commence with the prototype erection procedure. That is, sort of... Unfortunately, at the conclusion of my hardware fabrication, I still lacked an indoor facility for frame setup. I needed a space with a level floor that was climate controlled and out of the elements (lest they warp or require rework as a result of water damage), such that I could leave the parts in an interim state for a number of weeks as I worked through the details of the initial installation procedure. To this end, my friend Josh was kind enough to allow me to use his garage and workshop—although it was not exactly what I had in mind for an “empty space”. After I came by and surveyed the space, taking some measurements and figuring out what would be required for equipment relation, I figured we could probably make it work—but just barely. From my calculations, it looked like the extremities of the erected structure would probably fit within just a few inches of the walls.

After some serious reorganization of Josh’s garage goods, I began to set up the large wooden frame—almost exactly the same way that I outlined in the procedure that I had developed the year before. While I was not exactly

trying to erect something as large as six stories in height, I didn’t exactly have thousands of Levite helpers at my disposal, either. While I believe that the scale model erection process might be accomplished by ten trained men over the course of an hour or two, erection of the 22 foot scale model used one or two erecting the frame over the course of a week or two with a few hundred feet of rope for frame rigging—straddling some of Josh’s garage shelving and fitting within the

garage by mere inches—exactly as predicted. If my memory serves me correctly, the erection iteration began on or around 3/14/5777 on the Hebrew calendar (June 8th), as was completed on or around 6/28 (which is curiously

2 x 3/14) of 2017, which is interesting, considering that the project went public on 3/14/15. From time to time, it leaves me wondering if my efforts weren’t thwarted in part and stalled from time to time for these very

reasons.

As I did learn a number of things about God’s dwelling place itself over the course of the “proof of concept” model fabrication and erection process, the completion of the scale model structure marked a major project

milestone. Not only do does this model serve as an effective “proof of concept”, but the whole exercise really refined my understanding of some of the Hebrew nuance, which in turn gave me an even greater respect for

the brilliance of the design that is so concisely conveyed by a handful of divinely inspired Hebrew words in a mere chapter of the Bible text. Granted, the model did reveal that there remains room for learning on my

end and that there is room for many small engineering design improvements, but overall, the modeling exercise proved to be a success, and proved to me beyond a reasonable doubt that my original vision is more than a mere product of my own creativity or my own overactive imagination—as many members of the general religious public are likely to assume. It is practical and can be built exactly according to Exodus texts, unlike the

clunky counterpart rectangular “shoebox” models that I had surveyed in Israel the previous summer. The first “proof of concept” model, of course, is a far cry from what I believe needs to be built for future project

purposes under crowdfunding endeavors, but as they say, the horse needs to come before the cart.

After insightfully consulting on and graciously funding my “proof of concept” scale model, Brian offered another gift and incentive for me to further the Project 314 research and education outreach objectives. Subsequent

to dismantling the physical scale model (as Josh needed his garage space back) in July of 2017, Brian asked if I would be interested and willing to present my research at a conference of my choice, with him funding

my transportation, room and board, and conference entrance fees. Obviously, it is no small thing to speak at a conference; and neither is it a small thing to fund one, schedule one, or prepare for one. Consequently,

most conferences host speakers by invite only; and most conferences, needing to market their speakers to audiences, get speakers “locked in” a long time before the date of the conference itself. While I liked the idea

that Brian had proposed, I must say I struggled for a number of weeks while trying to figure out if or how I might be able to capitalize on the conference sponsorship opportunity.

For those who haven’t ventured outside of their local religious communities, there are lots of different conferences that take place in different places and over different periods of the calendar year, most of which are predicated on particular beliefs, institutional affiliations, or doctrinal professions. Obviously, with Project 314 founded as an independent organization of sorts with very pointed objectives and covering a very specialized scope, my options in finding compatible conferences tend to be somewhat limited, especially as organizers are skeptical as to how members of their particular communities might react to my research.

With Project 314 still being in its infancy, it is difficult but still necessary to be proactive and attempt to cultivate leads to events on a long term basis, which has been impractical and/or premature given the odd nature and unexpected progression of project development, which has been largely influenced by limited resources and the order of opportunities presented. All that being said, after doing some research, my friend Ali, who had attended many religious conferences over the course of her lifetime, recommended at some point in July of 2017 that I try to attend one of the archaeology conferences held in Boston in the fall of 2017.

Although I am no Indiana Jones or pottery-sifting archaeology enthusiast, the idea of attending the American Schools of Oriental Research (ASOR) conference made good sense, especially as there were a number of other related conferences being held the same weekend. To be more specific, there was an entire alphabet soup of other religious groups and archaeology conferences in the same vicinity, including BAR/BAS/ETS/NEAS/AAR/SBL, which stand for Bible Archaeology Review, Bible Archaeology Society, Evangelical Theological Society, Near East Archaeological Society, American Association of Religion, and the Society of Bible Literature, respectively. While it was originally my hope that I could find an opening or negotiate an opportunity to present before an audience, Ali suggested that I consider entering the conference as an exhibitor with a booth, rather than as a walk-in or presenter, such that I might fully engage attendees and present content to them on a more formal, professional, and personalized basis.

Although I had never been a vendor or exhibitor at a trade show before, I had some idea of what it would entail, having been to a number of engineering and book shows before. Also, I already had a number of props or elements that I need in order to make a full booth. From my Israel trip and prior speaking engagements, I already had generated special scroll sets and binders which contained project exegesis and erection procedure drawings. Since then, I added another binder with “proof of concept” scale modeling results. I also made some physical props that people could interact with, like the full scale single silver “talent” pieces that are grossly oversized on the rectangular model, as well as sample fabric sheet sets to give people a perspective of how loom woven fabrics are used in the tent construction. Perhaps most importantly, for shock value, I had an upside down reddish dome shape sitting on my exhibit table. While there was nothing particularly shocking about the bowl itself, people were shocked and amused by my one-line ice breaker, as I harkened unto them, “Candy from a stranger”? Let’s face it; almost nobody can resist the allure of a bowl full of chocolates, especially when they are free.

As can be expected, the chocolate gimmick was successful in drawing people into my booth area, and at that point, they felt at least a little bit obligated to hear me out and take a look at my props and animated video propaganda, which I created for the show.

As for video development, the balance of my preparation time between late summer of 2017 and the ASOR conference was dedicated to furthering the development of my CGI (Computer Generated Imagery) Tabernacle video, which

showcased some animated clips of the Tabernacle transitioning between the awkward traditional rectangular unit and the rediscovered round tent. While it seemed that only a moderate fraction of people present were religiously

inclined, it also seemed that most people were able to digest the ideas that I was presenting. However, this is not necessarily to say that I was effective in bringing them to any sort of conviction, or for that matter, able to inspire

them to care. Nevertheless, the ASOR show preparation proved to be yet another asset-developing period for the project, as after the show concluded, I was well equipped to produce a colorful and illustrated book that

compared and contrasted the “old” with the “new” models on a verse-by-verse basis.

Following the inception of the round Tabernacle restoration vision, it became apparent that I lacked a few key things that were necessary to publicly advance the Tabernacle research and restoration cause. One thing in particular is a product that explained the Tabernacle in its entirety while comparing it to known points of reference, which include the English Bible and traditional rectangular models. While the “EEE” Drawings might were effective in presenting the round model without any other content, it is likely that this lack of comparative context kept people from truly understanding and seeing the errors inherent to the existing tradition. When presented independently of the rectangular model, and without rebutting the old system, it seems that people were subconsciously inclined to cling to it as being valid as it is widely accepted and has stood the test of time.

Apart from not initially seeing the essential need for contrasting the two models, I also came to understand that level of detail included on EEE drawings were intimidating or overwhelming many people, especially those who were not technically trained or accustomed to ingesting such a high density presentation of content. While the content was highly condensed, clearly labeled, and arranged orderly, it was still like drinking through a fire hose for most people who were unfamiliar with the content.

Despite my apprehension, I believed that having a book in publication was essential to the projects’ success, even though this generation is gravitating away from paper publications and from reading. A book, after all, is considered to be indicative of an author's subject matter expertise, or at least of competence and a of path to credibility. Being devoid of religious credential, I needed something in my corner to stand as witness on my behalf—and essentially against the institutional status quo. Given the amount of technical information that needed to be conveyed, it was deemed to be prudent, if not completely necessary, to give people an expanded explanation of many of the details, along with a means to absorb and re-review the material at their own pace. Finally, the reality is that people want—and need—something more than just pictures, facts, and figures. They needed something to identify with and more background information to further contextualize the content—such that they might have a reason to be motivated or inspired them in conjunction with receiving the nuts-and-bolts education.

Having already invested so much time in conveying the ideas and engaging people on a number of different levels, writing

The House of El Shaddai (THOES) came naturally. Although this is not to say it would come easy, I finished my first draft in less than three months, which included learning yet another software platform for the graphic-intensive book content, as the book contains over 200 images and diagrams.

Created for English readers, THOES identifies and dissects cancerous portions of English Bible translations, and dispels the myths supporting the traditional "shoebox" Tabernacle arrangement. This work is essential as it takes a person who is open to the possibility of the traditional model and translations being incorrect to being certain—beyond a reasonable doubt—that the dome is the logical outworking of the Exodus texts, and not the mere figment of one eccentric engineer's imagination.

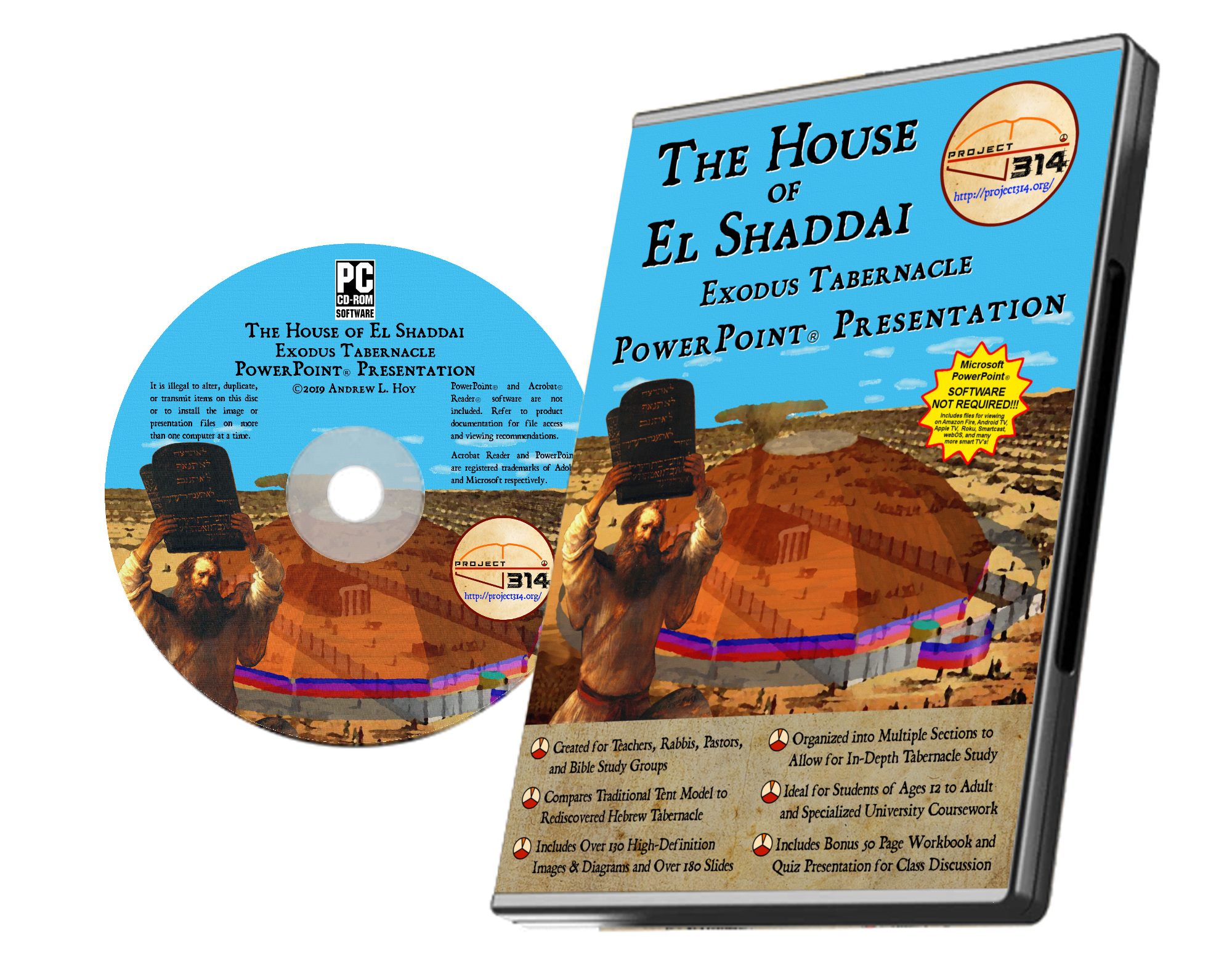

With THOES released and EGH editing and publishing efforts underway, my review of Amazon's

listing of specialty Tabernacle publications (e.g., Rose Publishing and ArtScroll) brought me to realize that there was another format that I had not originally considered, which is Microsoft PowerPoint.

Naturally,

while writing the Tabernacle books, I wanted make the material available electronically, especially as many people prefer to do studies and research by means of computer. Unfortunately, in surveying e-books and electronic reader platforms, the limited ability to publish graphic-rich content with interactive menu tools for user-driven study became apparent. Thus, the content from the THOES book was streamlined and packaged into PowerPoint format. Of course, the PowerPoint platform is likewise familiar and widely available to many educators and leaders. As

indicated in the

Spreading the Wordand

Schooling the Experts articles,

the importance of empowering others to teach this material cannot be understated.

In accordance with the project mission statement and recognizing the logical need for the further development educational materials became apparent, especially given the decreasing levels of Biblical literacy within religious

communities.

Unlike the Exodus Tabernacle PowerPoint and the God's Dwelling Place publications, the Questioning the Tabernacle Workbook is completely devoid of artwork, with exception of the cover

art, of course. Unlike other sources that give you the answers, this workbook employs the Socratic method (i.e., using questions to challenge presuppositions and draw out logical conclusions). Thus, this

book can be used autonomously to stimulate thinking, or as a companion to the PowerPoint or other books.

When writing the first Tabernacle book, it was my intention to make it appeal to widest possible audience; and in order to make

The House of El Shaddai the most inviting to native English speakers, detailed Hebrew references were deliberately excluded. So, after completing THOES—the book I felt compelled to write—I immediately began writing

Exploring God’s House (EGH), which is the book that I really wanted to write in order to address particulars of the Hebrew Exodus.

Although THOES covers the essential exegetical points, EGH was written using a different approach for a different audience and with a different intention. Unlike the progressive narrative format used for THOES, EGH uses a verse-by-verse approach, typically dedicating two pages of written content per each Bible verse. Being a Hebrew-centric extrapolation of THOES, EGH includes supplementary language tools and references for readers ranging from religious professionals and Biblical Hebrew enthusiasts (empowering everyday English readers with no Hebrew experience). Created for advocates and antagonists alike, EGH is written to allow readers to understand the deeper aspects of the ancient Hebrew revelation, which also preemptively defend the Tabernacle rediscovery against any pseudo-academic criticisms that might otherwise be levied against it.

Given the thorough and systematic approach, the final EGH draft is about 260 pages (as opposed to the nominal 200 pages of THOES). EGH editing is still underway and tentatively scheduled for 2020 publication.

With EGH nearly complete and THOES on the market, I began dedicating time towards other Tabernacle video, media, and modeling projects.

The first project initiated is one that I'm referring to as The Body in God's House or perhaps The Body of El Shaddai (either BIGH or BOES) which is a product series designed to correlate similarities between the Exodus Tabernacle (as God's dwelling place) and the human body (which is also understood to be a place of divine habitation). Where EGH is created as an essential guide to understanding the Exodus Tabernacle and its exegesis, BIGH is designed to build upon that knowledge and highlight the anatomical typology that is inherent to the divine Tabernacle design. Unlike the traditional rectangular "shoebox", this BIGH material is highlights the etymological, functional, geometric, and numerical similarities that show how the house of Betzalel or the "house in God's image" is really designed.

Conceptual media projects in this BIGH series range in complexity, tentatively including a coffee table book featuring professional artwork and illustrations, video presentations (PowerPoint and documentary style), and an academic / educational volume as well. Based upon the significance of this material, experienced videographers, publishers, and medical professionals are invited to contact Project 314 in order to partner with and participate in BIGH research, content development, and marketing efforts.

In conjunction with BIGH, another project entitled Receiving a Jewish Messiah (RJM) is underway, which is ultimately intended to help mend fences between Jews and Christians through Tabernacle-based revelations.

For centuries, Jews have accused Christians of eisegesis, which is the "process of interpreting text in such a way as to introduce one's own presuppositions, agendas or biases", in order to advocate New Testament writings and church doctrines. Of course, given the Project 314 round Tabernacle discovery, it's clear that Christianity has been doing more than reading into the text as many Christians have tried to "put God in a box", superimposing and force-fitting their christology into a shoebox Tabernacle design. Conversely, Jews have likewise modeled perhaps hundreds of synagogues in accordance with the presumed shoebox proportion.

The irony, of course, is that both Jews and Christians have been sitting on traditions, texts, and revelations that do speak to a Jewish messiah. With the Tabernacle being central to understanding the true Jewish messiah, RJM shows how the entire picture of the Tabernacle is a great fulfillment of Ezekiel's prophecy, whereby the two half-houses of Israel are joined together like a stick in God's hand. A studio PowerPoint production is currently in development (target release summer 2020).

As explained in the pages above, the past five years of this Tabernacle journey might best be described as another wilderness wandering—and a long, strange trip at that. Since the initial 3/14/15 launch of the Project 314 website and declaration of the big-picture "research and restoration" project mission statements, public response and public engagement might best be described as "mixed". To my knowledge and to my surprise, there have been no real attempts to reaffirm, research, or refute this model from the original Hebrew language—independent of my deliberate engagements—even though much of the design could be "reverse engineered" from free and preexisting Project 314 images. While more widespread understanding of God's dwelling place may be completely a matter of providential timing, it seems that those in favor of the Tabernacle rediscovery have largely been inclined to accept it on intuition or perhaps blind faith, whereas opponents apply similar intuition and respond via apathetic skepticism.

In any case, based on the historical return of the Jews to Jerusalem both in recent years and as well as in the the time of prophets Ezra and Haggai, this mixed and somewhat lukewarm response is something that can be expected. After all, many of the Jews that had been exiled into Babylon came out speaking like Babylonians (Nehemiah 13:24), which would indicate that they were largely ignorant of their own Scriptures. Even though the returning Jews were formally tasked with King Cyrus' mission statement to build God's house (Ezra 1:2-3), they refrained from doing their job for well over a decade. In other words, even though they were fully funded and liberated for such a purpose, it seems that ignorance and apathy were the greatest obstacles to building God's dwelling place then, and it stands to reason that little has since changed. This status and sentiment needs desperately to change.

To date, the Project 314 round Tabernacle discovery and journey has made two unfortunate truths evident: 1) Technically-inclined professionals are ignorant of scientific revelations and important details contained in Bible texts, and 2) Religious professionals are generally not trained, equipped, or inclined to handle relatively simple technical detail.

Fortunately, The solution to these two overlapping problems should be obvious; that is, the restoration of cross-disciplinary education. To that end, the Project 314 Bible STEM program was envisioned, whereby the Exodus Tabernacle revelation can be employed in teaching in the so-called STEM curriculum, which include Science, Technology, Engineering, and Mathematics.

As was the case in Nehemiah's day, you can't take the kids out of Babylon until you stop putting Babylon into the kids. Those interested in learning more about Bible-centered STEM materials should click on the button below.

Finally, after recent design and development work, the prototype for the first generation Tabernacle scale model kit is complete!

Given the need for a "hands-on" learning tool designed for children and adults alike, it seemed fitting to develop a Tabernacle model kit to facilitate a real-world Bible study, as well as facilitating dozens, if not hundreds of STEM-oriented lessons. With the overall dimensions scaled at 1 inch = 2 cubits, the assembled unit measures 50 inches across to bear resemblance to the dimensions listed in the Exodus texts. Furthermore, the Project 314 kit is comprised of over 400 pieces—unlike other Tabernacle model kits in the religious marketplace—to allow for direct 1:1 comparison to the hundreds of elements described in the Biblical narrative.

Apart from being the most accurate model available, the Project 314 Tabernacle kit is easy-to-assemble, making it ideal for home, church, or synagogue Bible study. As all parts are made to precision dimensions, the kit requires no measuring, no cutting, no glue, no mess, no complicated instructions, and no special tools for assembly. Young children may require supervision, as assembly requires some fine motor skills with smaller parts, and as some of the parts have sharp ends and could be choking hazards. Finally, in addition to being easy to assemble, the kit is also designed to be easily disassembled so the model may be easily stored and reused.

Due to specialized manufacturing processes, this first generation Tabernacle model will only be produced in a limited production run. Click the button below for further inquiries or pre-order to ensure you are among those first limited-edition production slot!

“Where will this journey take me next?”

In my opinion, this is not the question that anyone should be posing. The real question that needs to be put forth is, “Where will this journey take us next?”

After all, religion is not, and was never intended to be, a spectator sport. As such, the answer to the "what next" question remains to be seen, as the progress of the project is bound to be in direct proportion

to public participation and support.

To learn more, check out

The Tabernacle Manifesto,

or learn more about

Volunteering Time, Donating Funds

,

and Spreading the Word.